- Shop all catagories

- Automated Valves

- Gauges & accessories

- Hydraulics

- Pneumatics

- Water Meters

- Manual Valves

- IBR Certified Boiler Valves

- Non IBR Boiler Valves

- Pipe Fittings & Flanges

Product Information

Description

Additional information

Reviews

Description

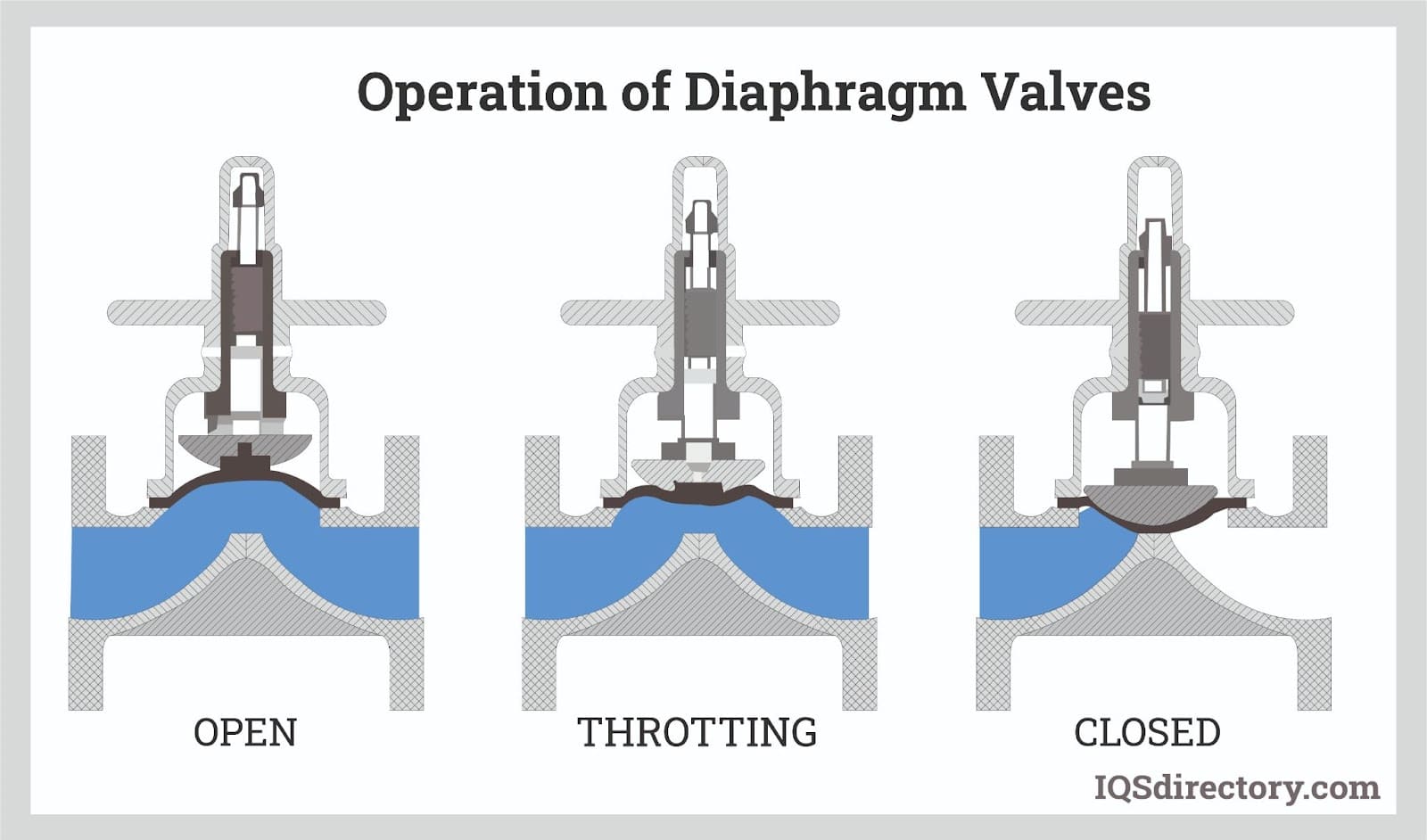

What is a Diaphragm Valve?

Diaphragm valves (or membrane valves) consists of a valve body with two or more ports, an elastomeric diaphragm, and a “weir or saddle” or seat upon which the diaphragm closes the valve. The valve body may be constructed from plastic, metal, wood or other materials depending on the intended use. A diaphragm valve, or membrane valve, is a valve with an elastomeric diaphragm and a seat upon which the diaphragm rests when it is closed. The flexible diaphragm obstructs, controls, or isolates the flow of fluids and acts as a flow control device. In a diaphragm valve, the diaphragm element flexes up or down to increase or decrease the fluid flow rate. The valve is sealed when the diaphragm is pressed firmly against its solid seat. Diaphragm valves are linear motion valves that monitor and control linear movement of fluids. Diaphragm valves are named for the flexible disc that blocks flow when it makes contact with the seat of the valve. The diaphragm is a pressure responsive component that is highly flexible and produces sufficient force to open, close, or control the function of the valve. Diaphragm valves are like pinch valves that use a liner as part of the valve body instead of a diaphragm.

Applications

Since diaphragm valves have minimal contact surfaces and are considered the cleanest valve (least likely to cause contamination) they have found widespread use in the pharmaceutical, food processing, and water treatment industries. Diaphragm valves are also used in the electronics industry, pulp and paper industry, power industry, and in high-purity water systems.Additional information

Additional information

| SIZE | 1/2" / 15MM, 3/4" / 20MM, 1" / 25MM, 11/2" / 40MM, 2" / 50MM, 21/2" / 65MM, 3" / 80MM, 4" / 100MM, 6" / 150MM |

|---|---|

| Ends |

Reviews