- Shop all catagories

- Automated Valves

- Gauges & accessories

- Hydraulics

- Pneumatics

- Water Meters

- Manual Valves

- IBR Certified Boiler Valves

- Non IBR Boiler Valves

- Pipe Fittings & Flanges

Direct Acting Solenoid Valve 2/2 way Normally Closed 1/4″

₹1,100 Original price was: ₹1,100.₹550Current price is: ₹550.

Brand : Airmax (Hydint) / Techno

Body : Aluminium

Seals : Nitrile

Pressure : Upto 8kg/cm2

Temperature : Upto 50 C

Media : Compressed Air

Product Information

Description

Additional information

Reviews

Description

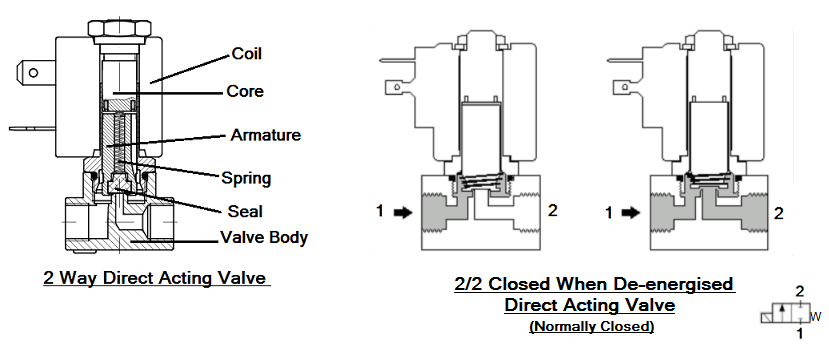

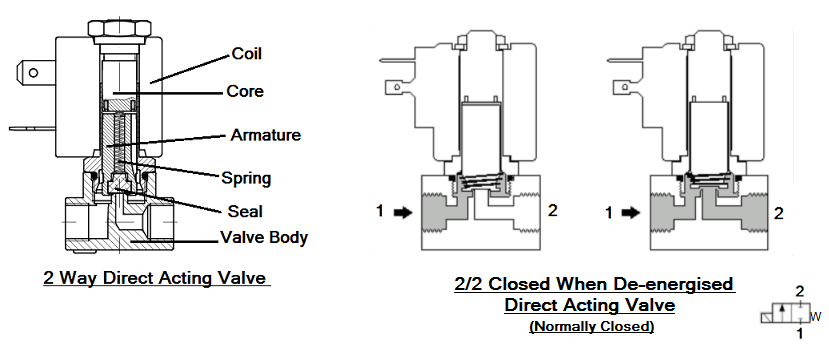

What is a Direct Acting Solenoid Valve?

Direct acting solenoid valve, also known as zero rated solenoid valves, are electro-mechanical valves that are used to control the flow of liquids or gases.

Direct acting solenoid valve is directly actuated by the solenoid and does not require any difference in pressure between the inlet and outlet ports in order to operate; they can therefore function from 0 bar upwards.

What are the benefits of Direct Acting Solenoid Valves?

- Can be used in negative pressure circuits

- Available in compact 2/2 way normally open or closed versions

- Includes Click-onTM solenoids that can be replaced without tools

- Number of valve body options makes it suitable for liquids and gases

Solenoid de-energised and valve is closed

The sealing element is directly connected to the plunger. When the solenoid is de-energised, the spring force presses the plunger on to the seat sealing the orifice. The plunger is only moved by energising the solenoid.

Solenoid energised and valve is open

When the solenoid is energised, the magnetic force lifts the plunger from the valve seat and the valve opens.

Maximum operating pressure and flow depend directly on the seat diameter (nominal diameter) and the force of the solenoid.

Click here to watch a video of how they work.

Benefits of Direct Acting Solenoid Valves.

Direct acting solenoid valves do not require any pressure differential to operate making them suitable for systems with low or no pressure. The lack of moving parts allows for very compact designs to be produced direct acting valves are available with Brass, Stainless Steel and Plastic bodied variants and a choice of seal materials making them suitable for most media types. Because they don’t normally rely on the use of very small (<1mm) internal holes or passageways direct acting valves can be more tolerant of small amounts of dirt in the media than servo-assisted types.

Additional information

Reviews